Specialized Solutions for Composite Machining – Tailored to Your Applications to Deliver Results

C6 Specialized Solutions for Composite Machining: Tailored to your applications to deliver results.

Delivering Precision Solutions for Automation to our customers. Learn More >>

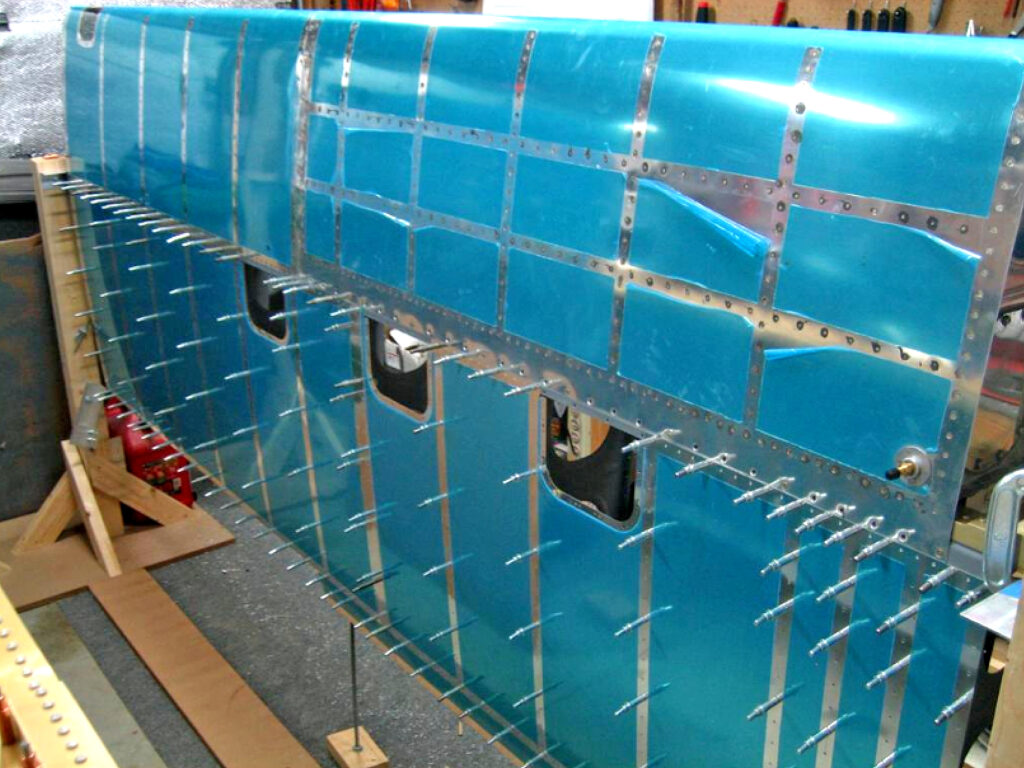

Aerospace manufacturing requires creating thousands of rivet holes with a countersink. Wavy or warped composite stock make automating the drilling and countersink process difficult.

Inconsistent countersink depth due to wavy or warped stock.

Manual work is eliminated!

C6 Specialized Solutions for Composite Machining: Tailored to your applications to deliver results.

End Mills for Machining Thermoplastics – Get the Perfect Finish for Plastic Parts. C6 has designed a line of millings cutter specifically for machining thermoplastics.

Speed-Up Your Composite Cutting with C6 Straight and Curve!

Airpro is the best dust evacuation solution for fast and effective clearing of your cutting path in composite materials.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.