Specialized Solutions for Composite Machining – Tailored to Your Applications to Deliver Results

C6 Specialized Solutions for Composite Machining: Tailored to your applications to deliver results.

Delivering Precision Solutions for Automation to our customers. Learn More >>

Whether you’re a long-time metalworking machinist looking into machining plastics, or a maybe you have been working with plastics for awhile and simply can’t find the secret to achieving consistent performance; the key to plastic machining is trial and error.

Just because your equipment and machining techniques are easily adaptive to machining plastic stock, According to the Larry Phippen, owner of Adapt Plastics in Loves Park, Ill., (www.adaptplastics.com) you’ll find that machining plastics require experimentation between different materials, different feed rates, and even different seasons.

“Most plastics have a high coefficient of thermal expansion and if your shop is not airconditioned a plastic will not cut the same way in summer that it does in winter. The data sheets usually have information on machining and that’s a good place to start, but the best way to really learn the material is to use it and experiment with it.” said Phippen.

Ultimately, it’s up to every individual operator to find what works for their machine depending on the job they are doing. So don’t be afraid of scrap, achieving perfect surface finish will require finding a perfect marriage between machine, material and cutting tool.

Metal’s natural rigidity makes it an ideal material for machining in high speed and high temperature environments. In the case of plastics, finding the right material for your machine and environment can be confusing.

When choosing your material, high rigidity in plastics such as fibre reinforced thermosetting plastics, glass reinforced nylons, acrylic or PEEK have good relative stiffness.

Check out this CNC Plastics Reference Guide for the pros and cons of the various plastics used in CNC machining.

Experimentation is required to find the proper machining parameters for your job. So test different plastics with your specific machine, with different speeds and feeds in order to find your desired result.

Ultimately, achieving high quality surface finishes relies on using the best cutting tool for the specific part. When looking for the right cutting tool there are a few things to consider, including: tool geometry, tool material, and number of flutes.

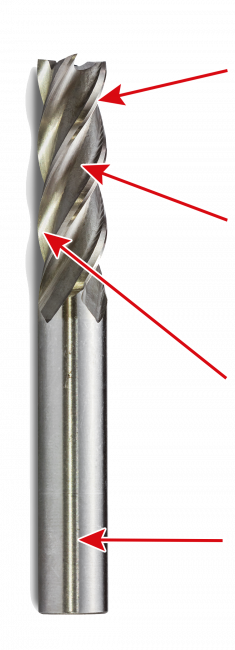

C6 end mills exclusively for thermoplastics feature all you see below to help you achieve the unparalleled finish quality.

Ultra-sharp cutting edges produce crystal-clear finishes.

Over-sized flutes improve chip evacuation for the high material removal rates associated with plastics.

Highly-polished flutes and flanks aid chip transport and improve surface finishes.

Special grade, very hard carbide maintains sharp edges longer.

C6 Specialized Solutions for Composite Machining: Tailored to your applications to deliver results.

Speed-Up Your Composite Cutting with C6 Straight and Curve!

Airpro is the best dust evacuation solution for fast and effective clearing of your cutting path in composite materials.

Automotive Manufacturing Solutions with C6 include cutting tools for machining all composite materials, carbon fiber and SMC components.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.